Boulder, Colorado-based Black Swift Technologies, developers of rugged dual-use uncrewed aircraft systems (UAS) designed for extreme tasks, recently received a $1.3M 2-year Direct to Phase II (D2P2) Small Business Innovation Research (SBIR) award from the AFWERX to revolutionize remote airfield operations through UAS-based soil integrity mapping.

AFWERX, the innovation arm of the Department of the Air Force (DAF) powered by the Air Force Research Laboratory (AFRL), teams across academia, industry, investment, interagency and international partners to unleash disruptive dual-use capabilities to help solve the Department’s most pressing challenges. Through the D2P2 prototyping phase, it contracts with small businesses such as Black Swift Technologies, to conduct further R&D to build and adapt their dual-use proposed solution to benefit the warfighter.

In this instance, AFWERX issued an Open Call for innovative defense-related dual-purpose solutions with a clear Air Force stakeholder need. Black Swift Technologies identified that critical need as the ability of the Department of Defense (DoD) to have its aircraft take off and land anywhere, at any time, to extend its global reach.

The problem is that such global operations often require the use or creation of unconventional airfield operational surface locations - sometimes literally on shaky ground. Unimproved runways, for example, often result in degraded aircraft handling. This increases the risks of aircraft damage and to pilot safety.

To minimize these risks, the traditional method for airfield evaluation involves personnel on the ground taking manual measurements of soil strength by repeatedly hammering a dynamic cone penetrometer (DCP) into the ground across different areas along a proposed landing site.

The DCP is an 8-pound stainless steel device consisting of two coupled shafts: the lower one contains an anvil and a pointed-tip and the paper one contains a sliding hammer that drops onto the anvil to drive the tip into the soil. The device measures soil strength by plotting the shaft’s penetration after each hammer blow (called the DCP index) against actual depth to either identify thicknesses and strengths at different layers or correlate against scientifically validated soil strength or pavement design parameters (e.g., the California Bearing Ratio).

In the field, this manual process consumes significant amounts of time. It can take a crew of 1 to 3 Airmen anywhere from 5 to 30 minutes per test section. Despite this time commitment, the procedure provides only partial information. It does not blanket the entire surface area, only those discrete hammered spots. Perhaps most concerning, in hot zones, this task poses a potential risk to the lives of those performing it.

For all of these reasons, AFRL has been evaluating other remote sensing technologies to perform this process more quickly, effectively and safely.

Black Swift Technology co-founders, Dr. Jack Elston and Dr. Maciej Stachura, combined, have over a decade of experience developing resilient and reliable drones, purpose-built to operate in the most extreme conditions, from wildland fires to volcanoes and hurricanes to tornadoes.

In early 2022, after several years of collaboration and testing with NASA, the Center for Environmental Technology (CET) at the University of Colorado, and Orbital Micro Systems working to industrialize the radiometer payload, the team released the first-of-its-kind soil moisture UAS to the commercial market.

The commercial soil moisture kit consisted of a custom radio-quiet version of the company’s fixed wing S2™ drone integrated with a mini high resolution sensor payload, advanced avionics and a passive microwave L-band radiometer.

The tech produces penetrative spatial and temporal images used to measure water content below the Earth’s surface, at root depths. In layman’s terms, it essentially acts as a special kind of thermometer that can measure how much heat something like soil gives off from a distance. It does this using a protected range of radio waves. It has a unique design that uses two different points of reference to ensure the readings’ accuracy. It basically looks at the heat coming from the ground and compares it to the heat it expects to see. This comparison helps users glean even tiny changes in how wet the soil is, down to about 1%. The way it determines the soil's wetness involves looking at the soil's temperature, what kind of surface it's on and what the soil is made of.

This high fidelity sensor on a drone changes the game because it allows coverage of across up to 600 acres per flight. The area that it can check will depend on how high the drone flies. After the initial reading, processing allows users to hone in on smaller areas to get even more detailed information.

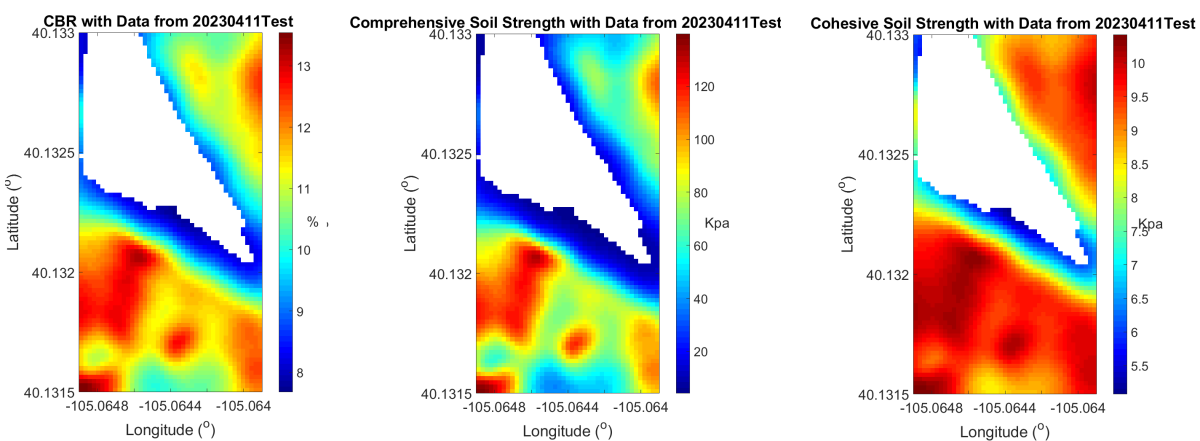

Elston and Stachura plan to take the original technology to the next level to use the soil moisture conditions of a given area to help determine soil strength. This will help users answer this question: Is the composition, depth, density, quantity and quality of soils on this site strong enough to withstand the rigors of our mission?

To do this, the two doubled down on innovation for their latest military design proposal.The work in this SBIR will focus on modifying the instrument, drone and processing software to expand the capability of the existing commercial soil mapping system to provide a measurement of soil integrity. Their team will develop new algorithms to extend the capabilities to mapping soil strength as cone index. They will also both improve and build upon that sensor for the soil moisture mission along with adding the new capability of measuring soil integrity. Part of this will involve improving the company’s proprietary digital radiometer detection technique by upgrading the L-band radiometer to provide enhanced interference detection and mitigation capabilities.

Understanding soil strength is critical for landing aircraft on existing and unimproved landing zones. For the Air Force, employing an updated version of Black Swift Technologies’ soil moisture system to map soil integrity for unimproved landing zones will provide forward air controllers with critical data to make decisions for C-130 landing operations anywhere in the world. The impact of this technology can span across over 160 air operation (AO) facilities and airfields, over 9,000 world-wide AO personnel, and 7.3 million annual aircraft operations.

Because of this SBIR Phase II win, Black Swift Technologies now also qualifies for AFWERX’s AFVentures Tactical Funding Increase (TACFI) funding. TACFI is a Supplemental Funding Pilot Program (SFPP) program focused on transitioning smaller-scale, tactical capabilities at the operational level.

TACFI enables small businesses to receive from $375,000 to $1.7 million in SBIR/STTR funds over a two-year period. For every dollar of SBIR/STTR funds, companies must also receive at least $1 of other government funding (i.e., non-SBIR/STTR) or $1 of private funding.

AFVentures collaborates with the Department of the Air Force (DAF) SBIR/STTR Program on this transition-focused funding opportunity. It aims to leapfrog technology over the “valley of death.” It capitalizes current SBIR/STTR Phase II efforts to turn prototypes into Air and Space Force Programs.

A TACFI win would secure Black Swift Technologies with a 2-year effort to design, build, and fly its prototypes with Agility Prime as a potential continuation of this new Phase II award.

In the meantime, Black Swift Technologies’ 5 meter target is to revolutionize forward air base civil engineering by validating runway integrity using soil moisture measurements. Once battlefield ready, the team has plans to incorporate these improvements into the current commercial offerings. Customers in construction, mining, agriculture, land management, and railway industries are already lining up.

If you missed Dr. Jack Elston on the Dawn of Drones Podcast, watch his episodes on demand:

Episode 37: https://www.youtube.com/watch?v=Kw2Ykyk2SQA

Episode 16: https://www.youtube.com/watch?v=7cVjuimJMfY

Episode 93: https://www.youtube.com/watch?v=eQMXqLQbXxY